0) Start With Use-Case (don’t skip)

- Primary use: fixed install, rental/touring, broadcast/studio, retail signage, immersive showroom, control room, outdoor billboard.

- Content type: powerpoint/video mix, sports/live camera, fine-detail UI, HDR films, static branding.

- Camera presence: will it be filmed/photographed? (dictates refresh/PWM, moiré control).

- Environment: indoor vs outdoor (sunlight, dust, rain, temperature swings).

- Viewing distance & size: define minimum viewing distance and pixel pitch window.

- Mounting constraints: wall can’t take load? need ground stack or truss? curves/corners?

- Noise/power limits: fans acceptable? circuit capacity? 110V vs 220V?

1) Pixel & LED Tech

1.1 Pixel Pitch (mm)

- What: center-to-center LED spacing (e.g., P1.5, P2.6, P3.9).

- Pros/Cons:

- Smaller pitch = sharper close-up, higher cost, more modules, lower max brightness (often).

- Larger pitch = cheaper, brighter, more moiré risk up close.

- Rules of thumb:

- Minimum comfortable distance ≈ 1–1.5× pitch in meters (P2.6 ≈ 2.6–4 m).

- If cameras involved, lean tighter pitch to reduce aliasing.

1.2 LED Package Type

- SMD (1515/2020/2121/3535)

- Pros: proven, broad ecosystem, serviceable.

- Cons: exposed diodes can chip; lower contrast than full-black COB.

- IMD/MiniLED clusters

- Pros: improved reliability/consistency over discrete SMD.

- Cons: newer, check repair process/parts.

- COB (Chip-on-Board)

- Pros: robust surface, great blacks, wider viewing angles, anti-collision.

- Cons: harder field repair, cost premium, vendor lock-in risk.

- GOB/Glue-on-Board (encapsulated SMD)

- Pros: impact/ingress protection, better cleaning.

- Cons: slight haze, can affect contrast if poor resin.

1.3 Diode Color: Black vs White

- Black-face LEDs: higher perceived contrast/black level, premium look; slightly less raw nit output.

- White-face LEDs: more raw brightness; lower perceived contrast, “milky” blacks in dim rooms.

1.4 Shader Mask / Surface Finish

- Matte, micro-louver, or black mask reduces reflections and moiré;

- Large mask lips protect LEDs but can narrow viewing angles.

1.5 LED Binning & Consistency

- Demand same BIN across the batch; check factory color/brightness binning reports to avoid patchwork tones.

2) Image Quality & Motion

2.1 Brightness (nits)

- Indoor: 600–1200 nits typical.

- Retail/front windows: 1500–3000 nits.

- Outdoor daylight: 4500–10,000 nits.

- Auto-dimming sensor is mandatory for comfort and energy.

2.2 Contrast & Black Level

- Influenced by LED face (black vs white), mask design, panel reflectivity.

- Ask for ANSI contrast numbers or demo in your lighting.

2.3 Refresh Rate vs PWM

- Refresh rate (Hz): how often the image updates (1920/3840/7680 Hz).

- PWM frequency: sub-pixel modulation rate; higher PWM reduces camera flicker/banding.

- For filming: target ≥3840 Hz refresh and high-PWM driver IC (flicker-free on high-shutter cameras).

2.4 Grayscale & Bit Depth

- True 14–16 bit processing helps gradients; beware “marketing bits.”

- Ask for low-level grayscale demos (dark ramps without sparkle/crush).

2.5 Color Gamut & White Point

- Verify sRGB/Rec.709 minimum; ask if HDR10/HLG supported end-to-end.

- White point calibration to D65 (or your target).

2.6 Uniformity & Calibration

- Factory calibration per panel and per module;

- Ask for camera-based calibration support and on-site re-cal workflow.

2.7 Viewing Angles

- Horizontal/Vertical spec plus off-axis color shift demo.

- Masks, COB coatings, and diode size affect angles.

2.8 Moiré Control (for cameras)

- Tighter pitch, matte masks, slight defocus, and angle control reduce moiré.

- Test with your camera/lens at your planned distances.

3) Electronics: Drivers, ICs, Scan, Cards

3.1 Driver IC Brand/Spec

- Reputable ICs (e.g., ICN/MBI) with high-PWM, low-ghosting, anti-smearing, true-dark performance.

3.2 Scan Ratio

- 1/8, 1/10, 1/16, etc. Lower denominator (e.g., 1/8) → generally brighter & better low-level, but costlier/denser electronics.

- High scan (e.g., 1/32) can flicker more and dim at low brightness.

3.3 Receiving Cards (per cabinet)

- Check brand/series (e.g., Novastar A8s/A10s Pro, Colorlight, Brompton data cards on certain systems).

- Features to verify: 10/12-bit pipelines, low latency modes, 3D LUTs, seam correction, module mapping, redundancy.

3.4 Sending/Control

- Senders/Processors: HDMI 2.0/2.1, DP, 12G-SDI, fiber inputs, scaler quality, genlock/framelock for broadcast, HDR pass-through, 10-bit pipeline.

- All-in-one media players (Novastar TB, etc.) for signage; simpler but less live-show control.

- Redundancy: dual senders, looped data, PSU backup.

3.5 Latency

- Critical for live/IMAG. Processor + mapping should keep end-to-end latency low (ask for measured ms).

4) Mechanics: Modules, Cabinets, Frames

4.1 Cabinet Type

- Fixed-install (thin, light, front-service)

- Pros: slim, neat; Cons: less robust for frequent handling.

- Rental/Touring (die-cast, quick-locks, edge protection)

- Pros: fast rig, robust; Cons: thicker/heavier, pricier hardware.

4.2 Cabinet Size & Tolerances

- Common: 500×500, 500×1000 mm; fine-pitch may be 480×540, etc.

- Tight flatness tolerance (<0.5 mm) reduces seams.

- Ask for auto/alignment pins and strong corner protection.

4.3 Serviceability

- Front-service magnets vs rear-service;

- Hot-swap modules/PSUs/receiving cards without power-down.

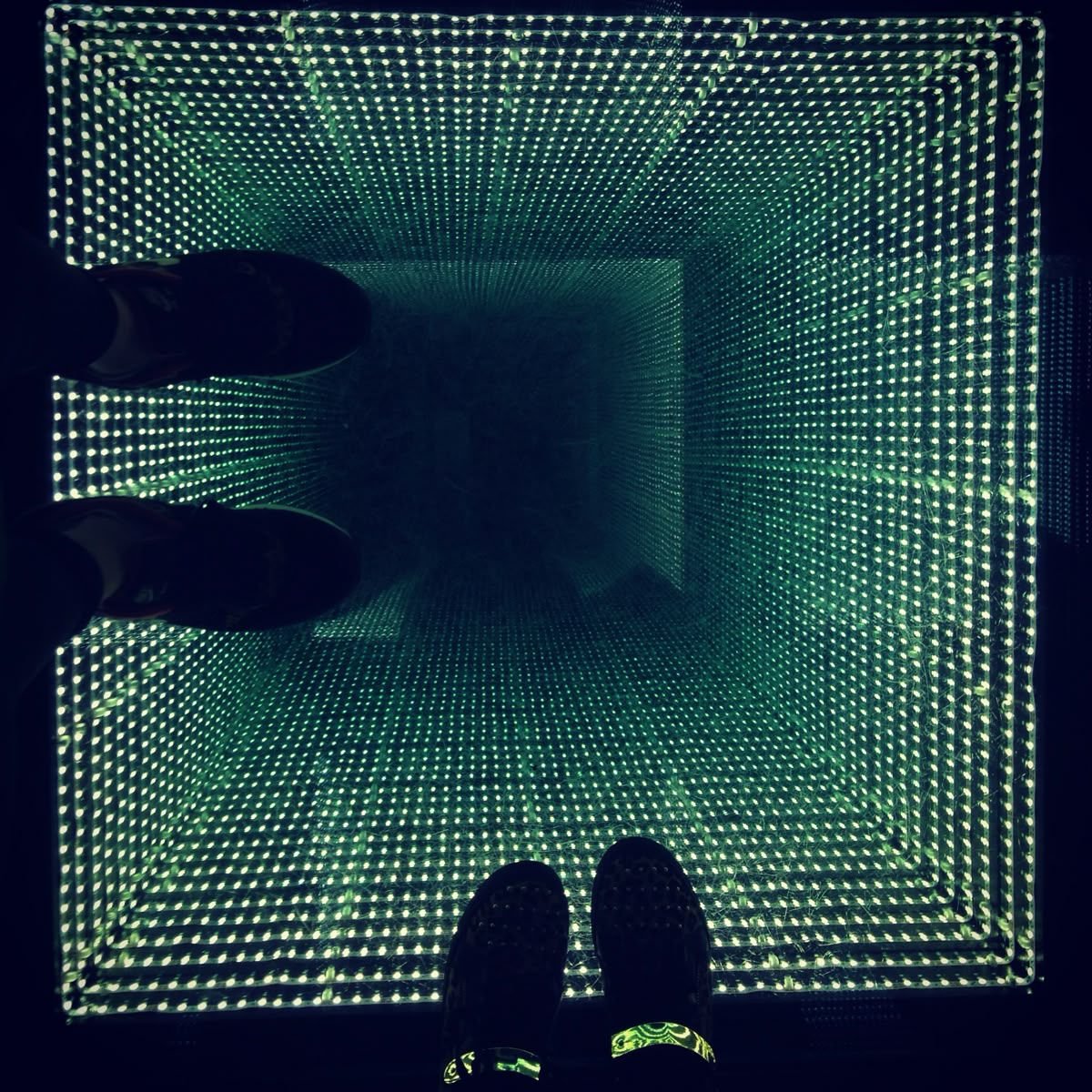

4.4 Curves & Corners

- Inner/outer curve kits, adjustable ± angles;

- 90° corners with special modules; edge masks to avoid exposed LEDs.

4.5 Protection & Durability

- COB/GOB for impact resistance;

- IK rating if public touchable; IP rating (see below).

4.6 Noise & Cooling

- Fanless (quiet, less airflow) vs active fan (cooler but noisy).

- Thermal design: heat-spreaders, derating at high ambient temps.

5) Installation & Rigging

5.1 Mounting Method

- Wall-mount frames, ground stack, or flown (truss/beam).

- Load ratings (TÜV), safety cables, quick-locks.

5.2 Structural & Permits

- Wall capacity (shear/pull-out), seismic/wind loads (outdoor).

- Local permits, landlord restrictions, façade rules.

5.3 Alignment & Commissioning

- Frame shimming, laser alignment, seam adjustments, color calibration on site.

5.4 Accessibility

- Front access for tight spaces; rigging points for service lifts.

6) Environment & Ruggedness

6.1 IP Rating

- Indoor: typically IP20–IP43;

- Outdoor: IP65 front/IP54 rear or better. Verify UV stability.

6.2 Operating Range

- Temperature & humidity windows; conformal-coated PCBs for humid/salty air.

6.3 Sunlight & Glare

- Polarization effects on sunglasses; anti-glare masks help.

6.4 EMC/EMI

- FCC/CE/ETL/UL compliance; low RF noise if near sensitive gear.

6.5 Fire & Safety

- Flame-retardant plastics, certified cabling, correct breakers and ground.

7) Power & Energy

7.1 Power Architecture

- Common-cathode (often lower heat/energy) vs common-anode.

- Redundant PSUs in critical installs.

7.2 Consumption

- Max vs typical draw (ask both); design circuits for worst case.

- Brightness scheduling & auto-dimming = huge savings.

7.3 Electrical

- 110/220 VAC compatibility, power factor, inrush current;

- Surge protection, SPD, UPS for processors.

8) Control System & Workflow

8.1 Processors

- Live events/broadcast: Brompton, Novastar flagship, Colorlight—look for genlock, 10-bit, HDR, low latency, seam/area correction, 3D LUTs.

- Signage: CMS with remote control, scheduling, health monitoring.

8.2 Connectivity & Distance

- CAT6/6A vs fiber for long runs;

- Data redundancy rings to survive single-point failures.

8.3 Software

- Mapping tools, auto-cal, remote diagnostics, RCFG profiles, EDID handling, presets.

9) Reliability, QA & Support

9.1 Burn-In & QA

- Request 72–168 hr burn-in report, dead-pixel counts, calibration logs.

- Ask for Factory Acceptance Test (FAT) video and Site Acceptance Test (SAT) plan.

9.2 Spares & MTBF

- Spare modules (2–5%), PSUs, receiving cards; MTBF statement; future diode EOL plans.

9.3 Warranty & RMA

- Parts + labor? Advance replacement? Local service partner? Turnaround times?

9.4 Batch Matching

- Lock your order to a single production batch when possible. Keep reserve stock from the same batch.

10) Compliance & Paperwork

- Certifications: UL/ETL (North America), CE (EU), FCC (EMI), ROHS.

- Documentation: wiring diagrams, rigging manuals, service manuals, color calibration profiles.

11) TCO, Hidden Costs & Logistics

- Processors/scalers, mounts/frames, rigging, truss, lifts, cabling, fiber converters.

- Installation labor, commissioning/calibration, permits, structural steel.

- Power bills (auto-dimming saves real money).

- Shipping/insurance, customs, lead time, after-sales service.

12) Option Matrix (what exists / what it’s good or bad at)

| Option | Best For | Pros | Cons | Watch-outs |

|---|---|---|---|---|

| SMD Black-face | Premium indoor, retail, showrooms | High contrast, broad ecosystem | Slightly less raw nits | Ask for matte mask, high-PWM IC |

| SMD White-face | Bright indoor/window | More raw brightness | Worse blacks/contrast | Looks washed in dim rooms |

| COB | Touchable/robust, fine pitch | Very durable, deep blacks, wide angle | Repair complexity, cost | Confirm local service & spare policy |

| GOB (encapsulated SMD) | Public areas, rental abuse | Impact/water resistance | Slight haze risk | Inspect in person for clarity |

| Fixed-install cabinets | Thin, clean installs | Slim, front-service | Not for constant re-rig | Confirm front-service depth |

| Rental cabinets | Touring/live events | Fast locks, protected edges | Thicker/heavier | Check corner wear, spares |

| High brightness (≥3000 nits) | Windows/outdoor | Cuts glare, daylight visible | Power/heat/noise | Auto-dimming + robust power planning |

| High refresh/PWM | Filming/live IMAG | Flicker-free, smooth motion | Higher cost | Verify with your camera test |

| Common-cathode | Energy-sensitive installs | Lower heat & draw | Not universal | Validate real-world meter readings |

| Front-service magnets | Tight spaces | No rear access needed | Magnet wear over time | Spares for magnets & tools |

| Curvable frames | Creative shapes | Visual impact | Complexity & cost | Tolerances to avoid seam gaps |