What “Micro RGB” Actually Means

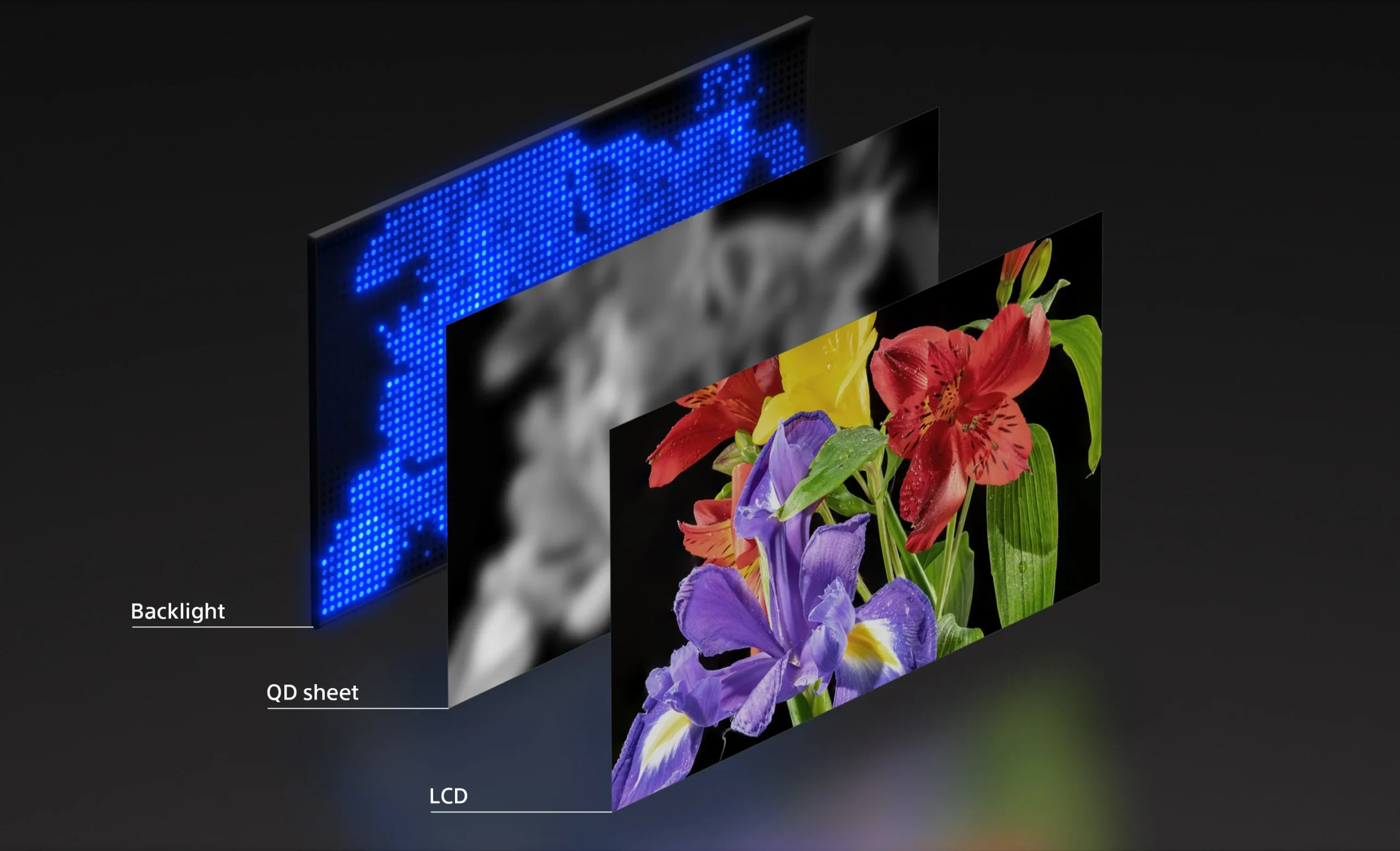

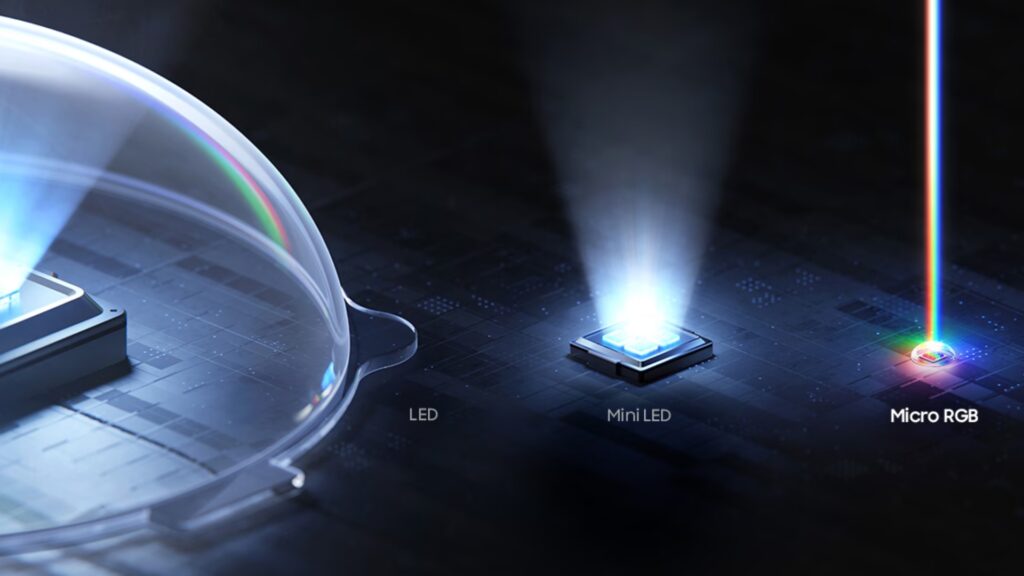

Micro RGB isn’t shorthand for “smaller LEDs.” It’s a description of how color is produced at the pixel level. Each subpixel is its own emissive element, fabricated directly in red, green, or blue, without color filters, without white subpixel tricks, without layered organic stacks that age at different rates.

This sounds technical, but the implications are visible. When red is actually red, not filtered white, brightness stops being a zero-sum game. When blue isn’t a chemically stressed organic layer fighting entropy, longevity stops being a design constraint. When subpixels are inorganic and self-emissive, heat, UV, and static imagery stop behaving like slow poison.

Micro RGB is often discussed alongside MicroLED, but the distinction is worth keeping sharp. MicroLED describes scale and fabrication method. Micro RGB describes color architecture. The two overlap, but they are not interchangeable. Plenty of MicroLED demos still rely on color conversion layers or phosphors. Micro RGB doesn’t.

That difference is why Micro RGB is interesting beyond spec sheets.

Why OLED’s Weaknesses Are Structural, Not Incremental

OLED improvements over the last decade have been incremental by necessity. Slightly better blue materials. Slightly smarter pixel shifting. Slightly higher peak brightness for slightly shorter durations. None of this changes the underlying truth: OLED pixels age, and they don’t age evenly.

That uneven aging has shaped interface design in ways that are now so normalized they barely register. Persistent UI elements fade. Transparent overlays are avoided. Bright static graphics are treated like liabilities. Even automotive OLED dashboards quietly assume a replacement cycle.

Micro RGB doesn’t age gracefully either—no display does—but it ages predictably. Inorganic emitters degrade on timelines that resemble industrial materials, not organic films. That predictability matters when displays are embedded into environments rather than products.

Transparent displays are where this contrast becomes unavoidable.

Transparent Displays Expose the Cracks

Transparent OLED has always been impressive in demos and fragile in deployment. The transparency itself is convincing, but the brightness penalty is severe, and the lifetime assumptions are optimistic. Transparent OLED works best in controlled lighting, limited duty cycles, and curated content loops.

Micro RGB changes the math. Because brightness is not filtered away, transparency doesn’t require sacrificing visibility. Because emitters are inorganic, exposure to ambient light is less destructive. Because pixels are discrete and robust, transparent displays can behave more like glass with light than glass with film.

For architectural applications, retail windows, museums, and transportation, this matters more than black levels or contrast ratios. Displays in these contexts aren’t “watched.” They coexist. They’re on for long hours. They’re exposed to sunlight. They’re expected to age without embarrassing themselves.

OLED struggles here not because it’s poorly engineered, but because it was never meant to live there.

Manufacturing Reality, Not Fantasy

The usual rebuttal to any OLED-replacement narrative is manufacturing. OLED is mature. OLED is scalable. OLED has yields. All true. Micro RGB fabrication is still complex, expensive, and yield-sensitive. Mass transfer remains a headache. Alignment tolerances are unforgiving. Everyone in the supply chain knows this.

But the conversation has shifted. The question is no longer whether Micro RGB can be manufactured at scale, but where it makes sense to do so first. The answer is not phones or TVs. It’s places where OLED’s weaknesses cost more than Micro RGB’s complexity.

Large-format transparent displays. Public installations with long duty cycles. Automotive and aviation glass. Commercial signage where replacement costs dwarf panel costs. In these contexts, Micro RGB doesn’t need to beat OLED on price. It only needs to stop failing in predictable ways.

That’s a lower bar than it sounds.

Design Freedom, Revisited

OLED unlocked new form factors but quietly constrained behavior. Designers learned what not to do. Micro RGB reopens some of those doors. Static content stops being taboo. Bright whites stop being dangerous. Transparent layers stop feeling like compromises.

This doesn’t mean interfaces will suddenly become louder or harsher. It means the rules change. It means displays can be treated less like living organisms and more like engineered surfaces. That shift is subtle, but it accumulates.

For designers working on transparent displays, this is especially noticeable. The difference between designing around a display and designing with one is often just confidence. Micro RGB encourages that confidence by removing some of the unspoken fragility.

OLED Won’t Vanish. It Will Retreat.

Obsolescence is rarely dramatic. OLED won’t disappear. It will narrow. It will remain excellent for personal devices, flexible applications, and cost-sensitive products where replacement is expected. It will continue to improve, but within its own boundaries.

Micro RGB doesn’t need to replace OLED everywhere to change the industry. It only needs to take the places OLED never quite belonged. Once that happens, expectations shift. Designers start asking different questions. Architects stop accepting dimness as a given. Engineers stop budgeting for burn-in as a line item.

That’s how technologies become obsolete—not when they fail, but when their compromises stop being the default.

Micro RGB is not inevitable. But it is inconvenient in the way that matters. And for OLED, that may be enough.